Your Address : Globalchemmade--Chemsol Industry Co., Ltd

Name:Chemsol Industry Co., Ltd

Type:Others

Tel:0393-4875693

Fax:86-010-80115555-7755

Email:info@chemsol.com.cn

Address:China(Mainland)

Products detail

| Product Name: | Sodium tripolyphosphate(stpp) |

|

| CAS No: | ||

| Product Type: | Inorganic Chemicals -> Inorganic acids | |

| Product spec: | Sodium tripolyphosphate(stpp)94% | |

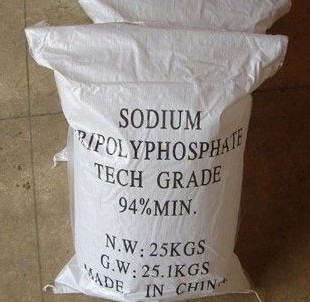

| Packing: | 25kg/pp bag | |

| Post Time: | 2011-12-12 | |

| Usage: | Main part being used as sapide helps the agent , soap synergist , water softener , processes hides giving tanning agent , dyeing an assistant, the effective powder that suspension liquid sells at reduced prices such as paint , advanced age soil , magnesia , calcium carbonate lama, makes paper using the greasy dirt aseptic , organic synthesis catalysator. Also be used petroleum products to refine , rubber whey bestowal , metal industry and medicine industrial to do the dispersant, but the solvation, use being unable to have broad as well as domestic bird processes aspect in synthal , food industry. 【Production Process:】 STPP is one of the most important ingredients in detergent powder formulation. Its chemical formula is Na5P3O5. The STPP preparation process is composed of three steps: preparation of phosphoric acid from phosphate rocks, sodium pyrophosphate from neutralization of the acid, and finally the formation of STPP by condensation and polymerization of the sodium pyrophosphate. There are two processes now in common use for preparing STPP | |

| Description: | Sodium Tripolyphosphate (STPP) 【Detailed introduction:】 Formula:Na5P3O10 Molecular Weight:367.86 H.S.CODE:28353100 CAS.NO.: 7758-29-4 Capacity:12000 MT/year Standard:GB9983-88 【Properties:】White powder; Melting point 622 °C ; Easily soluble in water; It has got salient chelating capacity to metal ions of Ca and Mg etc. and can soften hard water to make suspension into solution, alkalinity, without causticity . It is a surfactant, and has got outstanding emulsification to lubricants and fat. It has different bulk density, i.e. low density 0.35-0.5g/cm 3 , medium density 0.51-0.65g/cm3 and high density 0.66-0.9g/cm 3 . This product has two crystalline forms, namely phase I (high temperature phase) and phase II (low temperature phase). The chemical properties of the two phases are the same, and the difference between them lies in the thermostability, hygroscopicity, solubility and hydration heat when dissolving. 【CS T-T (Tech Grade) & CS T-F (Food Grade) Specification:】 Indexes CS T-T CS T-F Assay Na5P3O10 % ≥ 94.0 94.0 P2 O 5 % ≥ 57.0 57.0 Water Insoluble Matter % ≤ 0.10 0.05 Iron(Fe) % ≤ 0.01 0.015 PH value (1% water solution) 9.2-10.0 9.5-10.0 Heavy Metal (as Pb) % ≤ 0.001 Arsenic (As) % ≤ 0.0003 Fluoride (F) % ≤ 0.003 Ignition loss 1.0 / density (g/cm3) 0.35-0.9 0.35-0.9 【Application:】Main part being used as sapide helps the agent , soap synergist , water softener , processes hides giving tanning agent , dyeing an assistant, the effective powder that suspension liquid sells at reduced prices such as paint , advanced age soil , magnesia , calcium carbonate lama, makes paper using the greasy dirt aseptic , organic synthesis catalysator. Also be used petroleum products to refine , rubber whey bestowal , metal industry and medicine industrial to do the dispersant, but the solvation, use being unable to have broad as well as domestic bird processes aspect in synthal , food industry. 【Production Process:】 STPP is one of the most important ingredients in detergent powder formulation. Its chemical formula is Na5P3O5. The STPP preparation process is composed of three steps: preparation of phosphoric acid from phosphate rocks, sodium pyrophosphate from neutralization of the acid, and finally the formation of STPP by condensation and polymerization of the sodium pyrophosphate. There are two processes now in common use for preparing STPP: 1. Wet process Converse ingredients in the phosphate rocks into their corresponding sulfuric salt and phosphoric salt. The liquid phosphoric acid is neutralized in next section into sodium pyrophosphate, then the phosphate to be condensed and polymerized into STPP. 2. Thermal process Feed phosphate rocks, coke and silicate rocks into an electric furnace to obtain phosphorus. The phosphorus is burned, and phosphorus pentoxide is formed. The later is hydrated and polymerized into STPP. | |